The Art of Tailoring

The Neapolitan art of tailoring is a specific style of tailoring that originates from Naples, Italy. It is characterized by a unique blend of traditional techniques and modern design, resulting in garments that are both classic and contemporary.

One of the defining features of Neapolitan tailoring is the use of lightweight and breathable fabrics, such as wool, silk, and linen. These materials are ideal for the warm Mediterranean climate and allow for greater comfort and movement. Neapolitan tailors also use a variety of specialized techniques, such as "spalla camicia" (shirt shoulder) construction, which creates a natural and relaxed shoulder line.

Neapolitan tailors are known for their attention to detail and commitment to quality. Each garment is carefully crafted by hand, with a focus on precision and craftsmanship. Neapolitan jackets, for example, often feature hand-stitched lapels, buttonholes, and pockets.

In addition to traditional tailoring techniques, Neapolitan tailors are also known for their innovative approach to design. They often incorporate modern elements, such as slimmer silhouettes and bolder colors, while still maintaining the classic look and feel of traditional Neapolitan tailoring.

Overall, the Neapolitan art of tailoring is a unique and highly respected style of tailoring that has been passed down through generations of skilled craftsmen. It is a testament to the rich history and culture of Naples, and remains a popular choice for those seeking high-quality, bespoke garments.

How a garment is born: The Jacket

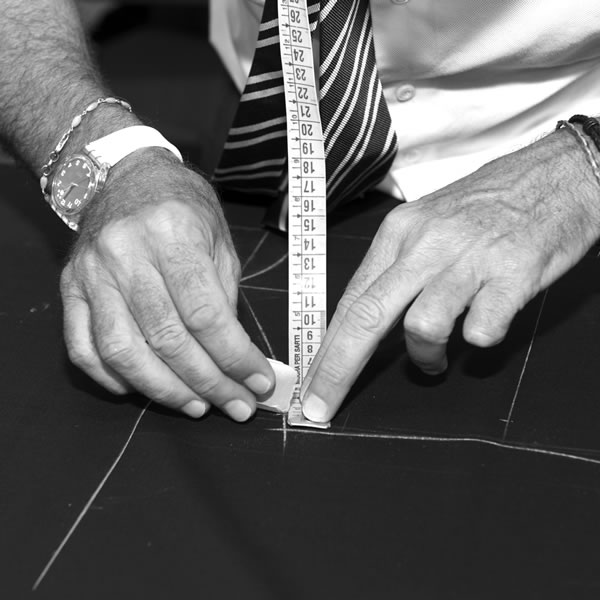

Time, skill, and creativity: these are some of the elements that make it possible to transform a fabric into a finished garment.

The life cycle of a 100% Made in Italy product is a complex process implying the participation of several resources capable of accompanying the garment through each stage of its transformation. A preliminary, decision-making phase involves the selection of raw materials: the creative team headed by Vincenzo Attolini is responsible for the choice of fabrics, linings, buttons and inner parts. Once the materials have been defined, the creative team passes the baton to the expert hands of the cutters, who trace the pattern on the fabric.

Checked jackets and patterned fabrics require more careful evaluation and greater craftsmanship in order to obtain garments that bring out the best of the pattern imprinted on the fabric, with perfectly matching and well-defined lines, impossible to reproduce in an industrial process.

Once cut, the fabric parts are basted, the pockets are fixed, the canvas and lining are applied and the shoulder straps are sewn.

Subsequently, shoulders and sleeves are basted, interspersing the union of each component with intermediate ironings and proceeding with the basting of the neck covering and undercollar.

The garment is almost complete when it passes straight to the “plumb” of the sleeves, a step in which the seam of the armhole is completed and checked. At this stage, the jacket is ready to accommodate the latest hand finishes, the buttons with their buttonholes and the label.

Each garment, then, undergoes strict quality controls in both the intermediate and final stages before delivery to the customer.

The production cycle ends with an impeccable end result, the outcome of the collective effort of a large group of people, behind whom there are years and years of study, acquired skills, creativity, commitment and tons of love.

Strictly made in Italy, or rather 100% made in Naples.